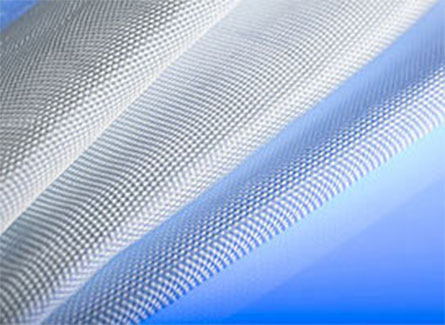

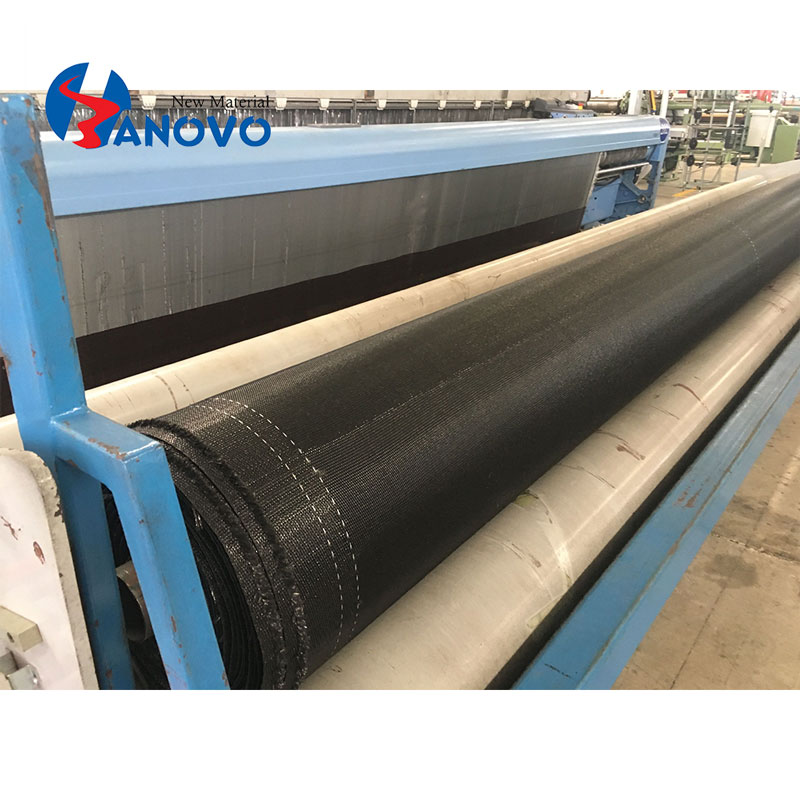

Nonwoven Geotextile

Hanovo PET Non-woven Geotextile is continuous filament needle punched non-woven geotextile made from polyester, formed by the process of needle punching and thermally bounding, offers optimum performance per unit weight.

Product Description

Hanovo PET Non-woven Geotextile is continuous filament needle punched non-woven geotextile made from polyester, formed by the process of needle punching and thermally bounding, offers optimum performance per unit weight.

Non-woven Geotextile provides effective and economical solution of separation, filtration, drainage, protection and reinforcement functions for engineering projects.

Applications Of Nonwoven Geotextile

1. Filtration

When water passes from a fine-grained to a coarse-grained layer, non-woven geotextiles can retain fine particles well. Such as when water flows from a sandy soil into a geotextile wrapped gravel drain.

2. Separation

To separate two layers of soil with different physical properties, such as the separation of road gravel from soft sub-base materials.

3. Drainage

To drain liquid or gas from the plane of the fabric, which leads to draining or venting of the soil, such as the gas vent layer in a landfill cap.

4. Reinforcement

To improve the load bearing capacity of a specific soil structure, such as the reinforcement of a retaining wall.

Nonwoven Geotextile Technical Data

| specification | Test Method | Unit | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ultimate Tensile Strength,MD | ASTM D4595 | kN/m | 7 | 11 | 14 | 17 | 19 | 24 | 27 | 30 | 37 | 41 |

| Ultimate Tensile Strength,TD | ASTM D4595 | kN/m | 6 | 10 | 12 | 15 | 17 | 21 | 25 | 28 | 34 | 38 |

| Tensile Elongation | ASTM D4595 | % | 45 | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 |

| Grab Tensile Elongation,MD | ASTM D4632 | N | 400 | 600 | 850 | 1000 | 1250 | 1450 | 1700 | 1900 | 2100 | 2500 |

| Grab Tensile Elongation,TD | ASTM D4632 | N | 350 | 550 | 700 | 900 | 1100 | 1250 | 1450 | 1600 | 1800 | 2150 |

| Grab Elongation | ASTM D4632 | % | 45 | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 |

| Trapezoid Tear Strength,MD | ASTM D4533 | N | 160 | 300 | 350 | 430 | 490 | 540 | 630 | 710 | 770 | 920 |

| Trapezoid Tear Strength,TD | ASTM D4533 | N | 140 | 270 | 330 | 400 | 450 | 510 | 610 | 690 | 750 | 900 |

| CBR Puncture Strength | ASTM D6241 | N | 1000 | 1800 | 2300 | 2700 | 3200 | 3600 | 4400 | 4800 | 5800 | 6900 |

| Apparent Opening Size O90 | ASTM D4751 | mm | 0.12 | 0.11 | 0.11 | 0.10 | 0.09 | 0.09 | 0/08 | 0.08 | 0.08 | 0.08 |

| Water Flow Rate Q100 | ASTM D4491 | L/m2/s | 250 | 235 | 220 | 200 | 285 | 165 | 125 | 110 | 90 | 80 |

| Weight | ASTM D5261 | g/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

| Thickness | ASTM D5199 | mm | 1.2 | 1.8 | 2.3 | 2.9 | 3.2 | 3.6 | 3.9 | 4.2 | 4.4 | 4.8 |

| Roll Width | m | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | |

| Roll Length | m | 300 | 200 | 250 | 100 | 100 | 100 | 80 | 80 | 50 | 50 |